Every minute counts

In industry, on average

unplanned stoppages cost up to

Per hour

helps you reduce these costs

by making your technical documentation

accessible, intelligent and intuitive

Every minute counts

In industry, on average

unplanned stoppages cost up to

Per hour

helps you reduce these costs

by making your technical documentation

accessible, intelligent and intuitive

1

Extended

downtime

2

Shortage

of labour

3

Lack of

efficiency

of maintenance

4

Difficult access

to technical

documention

5

Growing

complexity

of industrial

machines

Here’s how our solution

is transforming maintenance in several key areas.

Automotive sector

Challenges facing the sector:

• High downtime: On average, 29 hours of unplanned machine downtime per site per month.

• High costs: An average hourly cost of machine downtime of 1082,592$, representing an average annual cost of 377,28M$ per site.

Solution provided by Unity Forge :

• Reduced search time: By almost completely eliminating the 30-minute search in the documentation when a breakdown occurs.

• Instant access to documentation: Technicians have immediate access to the information they need via Unity Forge, which is integrated into the CMMS.

• Concrete results: With Unity Forge, the average annual cost per site has been reduced to 208,32 million$, representing a productivity gain of 45%.

Specific use case:

When an alert occurs on a machine, Unity Forge automatically provides procedures to follow, enabling operators to resolve problems more quickly and get production lines back up and running without delay.

Heavy industry

Challenges facing the sector:

• Complex equipment: Massive, complex machines requiring precise maintenance.

• High shutdown costs: With an average hourly cost of 151,1136$, machine shutdowns result in average annual costs of 56,64 million$ per site.

Solution provided by Unity Forge :

• Access to comprehensive knowledge: Efficient management of various technical documents, including electrical and mechanical drawings.

• Reduced downtime: By providing the necessary information quickly, Unity Forge helps to reduce intervention time.

• Concrete results: Average annual cost per site reduced to 32.304M$, representing a 43% productivity gain.

Specific use case:

In the event of a breakdown, a technician can access detailed plans and specific instructions via Unity Forge, making it easier to diagnose and repair complex machines.

Consumer Products

Challenges facing the sector:

• Continuous demand: The need to maintain uninterrupted production to meet consumer expectations.

• Costly downtime: An average of 25 hours of unplanned machine downtime per site per month, with an average hourly cost of 19 008$.

Solution provided by Unity Forge :

• Increased efficiency: Reduced documentation search time, allowing operators to concentrate on troubleshooting.

• Multimodal document management: Easier access to diagrams, tables and instructions, even for less experienced operators.

• Concrete results: Average annual cost per site reduced from 5,76M$ to 3,744M$, representing a 35% productivity gain.

Specific use case:

A new technician can use Unity Forge to receive step-by-step guidance during an intervention, reducing errors and speeding up the time it takes to get equipment back into service.

Oil & Gas

Sector challenges:

• Critical environments: Operations often in difficult conditions where shutdowns are particularly costly.

• Very high hourly costs: An average hourly cost of machine stoppages of 177,312$, with average annual costs of 67,2M$ per site.

Solution provided by Unity Forge :

• Optimisation of interventions: Significant reduction in time spent searching for information, crucial in environments where every minute counts.

• Seamless integration: Unity Forge integrates with existing systems, avoiding additional disruption.

• Concrete results: Average annual cost per site reduced to 38.112M$, representing a 43% productivity gain.

Specific use case:

Did you know?

On average, Fortune Global 500 sites

lose 27 hours per site per month

due to unforeseen breakdowns,

with an average cost

of 489 600$ per hour of downtime,

resulting in a worldwide loss

of 794,88 billion$ per year.

1

Extended

downtime

3

Lack of

efficiency

of maintenance

2

Shortage

of labour

4

Difficult access

to technical

documention

5

Growing

complexity

of industrial

machines

Here’s how our solution

is transforming maintenance in several key areas.

Automotive sector

Challenges facing the sector:

• High downtime: On average, 29 hours of unplanned machine downtime per site per month.

• High costs: An average hourly cost of machine downtime of 1082,592$, representing an average annual cost of 377,28M$ per site.

Solution provided by Unity Forge :

• Reduced search time: By almost completely eliminating the 30-minute search in the documentation when a breakdown occurs.

• Instant access to documentation: Technicians have immediate access to the information they need via Unity Forge, which is integrated into the CMMS.

• Concrete results: With Unity Forge, the average annual cost per site has been reduced to 208,32 million$, representing a productivity gain of 45%.

Specific use case:

When an alert occurs on a machine, Unity Forge automatically provides procedures to follow, enabling operators to resolve problems more quickly and get production lines back up and running without delay.

Heavy industry

Challenges facing the sector:

• Complex equipment: Massive, complex machines requiring precise maintenance.

• High shutdown costs: With an average hourly cost of 151,1136$, machine shutdowns result in average annual costs of 56,64 million$ per site.

Solution provided by Unity Forge :

• Access to comprehensive knowledge: Efficient management of various technical documents, including electrical and mechanical drawings.

• Reduced downtime: By providing the necessary information quickly, Unity Forge helps to reduce intervention time.

• Concrete results: Average annual cost per site reduced to 32.304M$, representing a 43% productivity gain.

Specific use case:

In the event of a breakdown, a technician can access detailed plans and specific instructions via Unity Forge, making it easier to diagnose and repair complex machines.

Consumer Products

Challenges facing the sector:

• Continuous demand: The need to maintain uninterrupted production to meet consumer expectations.

• Costly downtime: An average of 25 hours of unplanned machine downtime per site per month, with an average hourly cost of 19 008$.

Solution provided by Unity Forge :

• Increased efficiency: Reduced documentation search time, allowing operators to concentrate on troubleshooting.

• Multimodal document management: Easier access to diagrams, tables and instructions, even for less experienced operators.

• Concrete results: Average annual cost per site reduced from 5,76M$ to 3,744M$, representing a 35% productivity gain.

Specific use case:

A new technician can use Unity Forge to receive step-by-step guidance during an intervention, reducing errors and speeding up the time it takes to get equipment back into service.

Oil & Gas

Sector challenges:

• Critical environments: Operations often in difficult conditions where shutdowns are particularly costly.

• Very high hourly costs: An average hourly cost of machine stoppages of 177,312$, with average annual costs of 67,2M$ per site.

Solution provided by Unity Forge :

• Optimisation of interventions: Significant reduction in time spent searching for information, crucial in environments where every minute counts.

• Seamless integration: Unity Forge integrates with existing systems, avoiding additional disruption.

• Concrete results: Average annual cost per site reduced to 38.112M$, representing a 43% productivity gain.

Specific use case:

Did you know?

On average, Fortune Global 500 sites

lose 27 hours per site per month

due to unforeseen breakdowns,

with an average cost

of 489 600$ per hour of downtime,

resulting in a worldwide loss

of 794,88 billion$ per year.

1

Extended

downtime

3

Lack of

efficiency

of maintenance

2

Shortage

of labour

4

Difficult access

to technical

documention

5

Growing

complexity

of industrial

machines

Here’s how our solution

is transforming maintenance in several key areas.

Automotive sector

Challenges facing the sector:

• High downtime: On average, 29 hours of unplanned machine downtime per site per month.

• High costs: An average hourly cost of machine downtime of 1082,592$, representing an average annual cost of 377,28M$ per site.

Solution provided by Unity Forge :

• Reduced search time: By almost completely eliminating the 30-minute search in the documentation when a breakdown occurs.

• Instant access to documentation: Technicians have immediate access to the information they need via Unity Forge, which is integrated into the CMMS.

• Concrete results: With Unity Forge, the average annual cost per site has been reduced to 208,32 million$, representing a productivity gain of 45%.

Specific use case:

When an alert occurs on a machine, Unity Forge automatically provides procedures to follow, enabling operators to resolve problems more quickly and get production lines back up and running without delay.

Heavy industry

Challenges facing the sector:

• Complex equipment: Massive, complex machines requiring precise maintenance.

• High shutdown costs: With an average hourly cost of 151,1136$, machine shutdowns result in average annual costs of 56,64 million$ per site.

Solution provided by Unity Forge :

• Access to comprehensive knowledge: Efficient management of various technical documents, including electrical and mechanical drawings.

• Reduced downtime: By providing the necessary information quickly, Unity Forge helps to reduce intervention time.

• Concrete results: Average annual cost per site reduced to 32.304M$, representing a 43% productivity gain.

Specific use case:

In the event of a breakdown, a technician can access detailed plans and specific instructions via Unity Forge, making it easier to diagnose and repair complex machines.

Consumer Products

Challenges facing the sector:

• Continuous demand: The need to maintain uninterrupted production to meet consumer expectations.

• Costly downtime: An average of 25 hours of unplanned machine downtime per site per month, with an average hourly cost of 19 008$.

Solution provided by Unity Forge :

• Increased efficiency: Reduced documentation search time, allowing operators to concentrate on troubleshooting.

• Multimodal document management: Easier access to diagrams, tables and instructions, even for less experienced operators.

• Concrete results: Average annual cost per site reduced from 5,76M$ to 3,744M$, representing a 35% productivity gain.

Specific use case:

A new technician can use Unity Forge to receive step-by-step guidance during an intervention, reducing errors and speeding up the time it takes to get equipment back into service.

Oil & Gas

Sector challenges:

• Critical environments: Operations often in difficult conditions where shutdowns are particularly costly.

• Very high hourly costs: An average hourly cost of machine stoppages of 177,312$, with average annual costs of 67,2M$ per site.

Solution provided by Unity Forge :

• Optimisation of interventions: Significant reduction in time spent searching for information, crucial in environments where every minute counts.

• Seamless integration: Unity Forge integrates with existing systems, avoiding additional disruption.

• Concrete results: Average annual cost per site reduced to 38.112M$, representing a 43% productivity gain.

Specific use case:

Did you know?

On average, Fortune Global 500 sites

lose 27 hours per site per month

due to unforeseen breakdowns,

with an average cost

of 489 600$ per hour of downtime,

resulting in a worldwide loss

of 794,88 billion$ per year.

Overall maintenance time

due to machine downtime

%

of time

for searching

for information

%

of time

for intervention

on machines

- 50%

%

productivity

gain

%

of time

for searching

for information

%

of time

for intervention

on machines

- 90%

- 100%

Overall maintenance time

due to machine downtime

%

of time

for searching

for information

%

of time

for intervention

on machines

- 50%

%

productivity

gain

%

of time

for searching

for information

%

of time

for intervention

on machines

- 90%

- 100%

Transform

your maintenance operations

with

Unity Forge helps you reduce downtime,

improve intervention efficiency,

and maximize the reliability of your industrial equipment.

Here are the measurable benefits of our solution.

Measurable return on investment

Unity Forge has a direct impact

on the performance of your industrial sites

Up to 90 %

reduction

in search time

accounts for 50%

of unplanned

downtime.

By drastically reducing

this time,

Unity Forge accelerates

recovery.

Optimization

of downtime

costs

reduces

the colossal costs

associated with

downtime,

especially in

in critical sectors

such as automotive

or heavy industry.

Improvement

in the precisions

of interventions

Reduce

human error

thanks to clear

contextualized information.

Transform

your maintenance operations

with

Unity Forge helps you reduce downtime,

improve intervention efficiency,

and maximize the reliability of your industrial equipment.

Here are the measurable benefits of our solution.

Measurable return

on investment

Unity Forge has a direct impact

on the performance of your industrial sites

Up to 90 %

reduction

in search time

accounts for 50%

of unplanned downtime.

By drastically

reducing this time,

Unity Forge

accelerates recovery.

Optimization

of downtime

costs

the colossal costs

associated with downtime,

especially in in critical sectors

such as automotive

or heavy industry.

Improvement

in the precisions

of interventions

Reduce human error

thanks to clear

contextualized information.

Transform

your maintenance operations

with

Unity Forge helps you reduce downtime,

improve intervention efficiency,

and maximize the reliability of your industrial equipment.

Here are the measurable benefits of our solution.

Measurable return

on investment

Unity Forge has a direct impact

on the performance of your industrial sites

Up to 90 %

reduction

in search time

accounts for 50%

of unplanned downtime.

By drastically

reducing this time,

Unity Forge

accelerates recovery.

Optimization

of downtime

costs

Every minute saved reduces

the colossal costs

associated with downtime,

especially in in critical sectors

such as automotive

or heavy industry.

Improvement

in the precisions

of interventions

Reduce

human error

thanks to clear

contextualized

information.

Simplify

industrial maintenance

Unity Forge is an AI platform designed to address

the major challenges of industrial maintenance:

reducing downtime, improving access to information

and optimize interventions.

Simplify

industrial maintenance

Unity Forge is an AI platform

designed to address

the major challenges of industrial maintenance:

reducing downtime,

improving access to information

and optimize interventions.

An AI

dedicated to industry

Industry-specific

Unity Forge is based on a language model specifically designed to understand the terminology, processes and requirements of your industry.

Ergonomics and performance

The solution is designed to provide precise answers to the real needs of operators and technical teams.

AI that knows your machines

at your fingertips

In-depth knowledge

Unity Forge draws on all your machine documentation, whether it comes from your teams or your suppliers.

Learning in the field

Every internal note, operational tip or feedback is exploited to provide highly relevant assistance.

Customized support

The solution adapts to the specific features of your equipment, guaranteeing precise diagnostics and optimum support.

An AI

dedicated to industry

Industry-specific

Unity Forge is based on a language model specifically designed to understand the terminology, processes and requirements of your industry.

Ergonomics and performance

The solution is designed to provide precise answers to the real needs of operators and technical teams.

AI that knows your machines

at your fingertips

In-depth knowledge

Unity Forge draws on all your machine documentation, whether it comes from your teams or your suppliers.

Learning in the field

Every internal note, operational tip or feedback is exploited to provide highly relevant assistance.

Customized support

The solution adapts to the specific features of your equipment, guaranteeing precise diagnostics and optimum support.

An AI

dedicated to industry

Industry-specific

Unity Forge is based on a language model specifically designed to understand the terminology, processes and requirements of your industry.

Ergonomics and performance

The solution is designed to provide precise answers to the real needs of operators and technical teams.

AI that knows your machines

at your fingertips

In-depth knowledge

Unity Forge draws on all your machine documentation, whether it comes from your teams or your suppliers.

Learning in the field

Every internal note, operational tip or feedback is exploited to provide highly relevant assistance.

Customized support

The solution adapts to the specific features of your equipment, guaranteeing precise diagnostics and optimum support.

Problems solved

Extended downtime

Significantly reduce

downtime thanks to

rapid access to critical data.

Shortage of manpower

Provide intelligent support

for your operators,

even inexperienced operators.

Complex documentation

Centralize your technical documents,

whatever their format

(diagrams, plans, videos).

Problems solved

Extended downtime

Significantly reduce

downtime thanks to

rapid access to critical data.

Shortage of manpower

Provide intelligent support

for your operators,

even inexperienced operators.

Complex documentation

Centralize your technical documents,

whatever their format

(diagrams, plans, videos).

Key features

Instant

access

Smart search

and contextual search

to quickly locate

essential information.

Unified management

of multimodal document

Seamless integration

of text files,

3D schematics, electrical

mechanical drawings.

Seamless

integration

Full compatibility

with your existing systems

(CMMS, ERP).

Advanced

diagnostics

Rapid fault analysis

based on available data

and historical data.

Proactive

recommendation

Anticipate problems

with suggestions

based on collected data.

Key features

Instant

access

Smart search

and contextual search

to quickly locate

essential information.

Unified management

of multimodal document

Seamless integration

of text files,

3D schematics, electrical

mechanical drawings.

Seamless

integration

Full compatibility

with your existing systems

(CMMS, ERP).

Advanced

diagnostics

Rapid fault analysis

based on available data

and historical data.

Proactive

recommendation

Anticipate problems

with suggestions

based on collected data.

Key features

Instant

access

Smart search

and contextual search

to quickly locate

essential information.

Unified management

of multimodal document

Seamless integration

of text files,

3D schematics, electrical

mechanical drawings.

Seamless

integration

Full compatibility

with your existing systems

(CMMS, ERP).

Advanced

diagnostics

Rapid fault analysis

based on available data

and historical data.

Proactive

recommendation

Anticipate problems

with suggestions

based on collected data.

A solution

designed for industry

Confidentiality and security

Secure hosting in a private cloud

or directly at the customer’s site

for total control.

Continuous evolution

Unity Forge is constantly improving

thanks to user feedback

and data collected in the field.

A solution

designed for industry

Confidentiality and security

Secure hosting in a private cloud

or directly at the customer’s site

for total control.

Continuous evolution

Unity Forge is constantly improving

thanks to user feedback

and data collected in the field.

Significant sector benefits

Automotive

Reduce

in average annual

per site from

377,28M$ to 208,32M$,

a productivity gain

of

%

Consumer

Products

Reduce

in average annual

per site from

5,76M$ to 3,744M$,

a productivity gain

of

%

Heavy

industry

Reduce

in average annual

per site from

56,64M$ to 32,304M$,

a productivity gain

of

%

Oil

& Gas

Reduce

in average annual

per site from

67,2M$ to 38,112M$,

a productivity gain

of

%

Significant sector benefits

Automotive

Reduce

in average annual

per site from

377,28M$ to 208,32M$,

a productivity gain

of

%

Consumer

Products

Reduce

in average annual

per site from

5,76M$ to 3,744M$,

a productivity gain

of

%

Heavy

industry

Reduce

in average annual

per site from

56,64M$ to 32,304M$,

a productivity gain

of

%

Oil

& Gas

Reduce

in average annual

per site from

67,2M$ to 38,112M$,

a productivity gain

of

%

Significant sector benefits

Automotive

Reduce

in average annual

per site from

377,28M$ to 208,32M$,

a productivity gain

of

%

Consumer

Products

Reduce

in average annual

per site from

5,76M$ to 3,744M$,

a productivity gain

of

%

Heavy

industry

Reduce

in average annual

per site from

56,64M$ to 32,304M$,

a productivity gain

of

%

Oil

& Gas

Reduce

in average annual

per site from

67,2M$ to 38,112M$,

a productivity gain

of

%

A solution designed for the future

Unity Forge not only meets your immediate needs,

but also supports your transition to enhanced maintenance.

Automatic

scalability

The solution improves

continuously

thanks to the data collected

and user feedback.

Lower

training costs

Thanks to intelligent support,

even inexperienced operators

can operate efficiently

without the need

for time-consuming training.

Continuous

improvement

and recommendations

become more precise

over time,

adapting to the specifics

of your operations.

Invest in the future

of your industrial maintenance

with

A solution designed

for the future

Unity Forge not only meets your immediate needs,

but also supports your transition

to enhanced maintenance.

Automatic

scalability

The solution improves continuously

thanks to the data collected

and user feedback.

Lower

training costs

Thanks to intelligent support,

even inexperienced operators

can operate efficiently

without the need

for time-consuming training.

Continuous

improvement

and recommendations

become more precise over time,

adapting to the specifics

of your operations.

Invest in the future

of your industrial maintenance

with

A solution designed

for the future

Unity Forge not only meets

your immediate needs,

but also supports your transition

to enhanced maintenance.

Automatic

scalability

The solution improves

continuously

thanks to the data collected

and user feedback.

Lower

training costs

Thanks to intelligent support,

even inexperienced operators

can operate efficiently

without the need

for time-consuming training.

Continuous

improvement

and recommendations

become more precise over time,

adapting to the specifics

of your operations.

Invest in the future

of your industrial maintenance

with

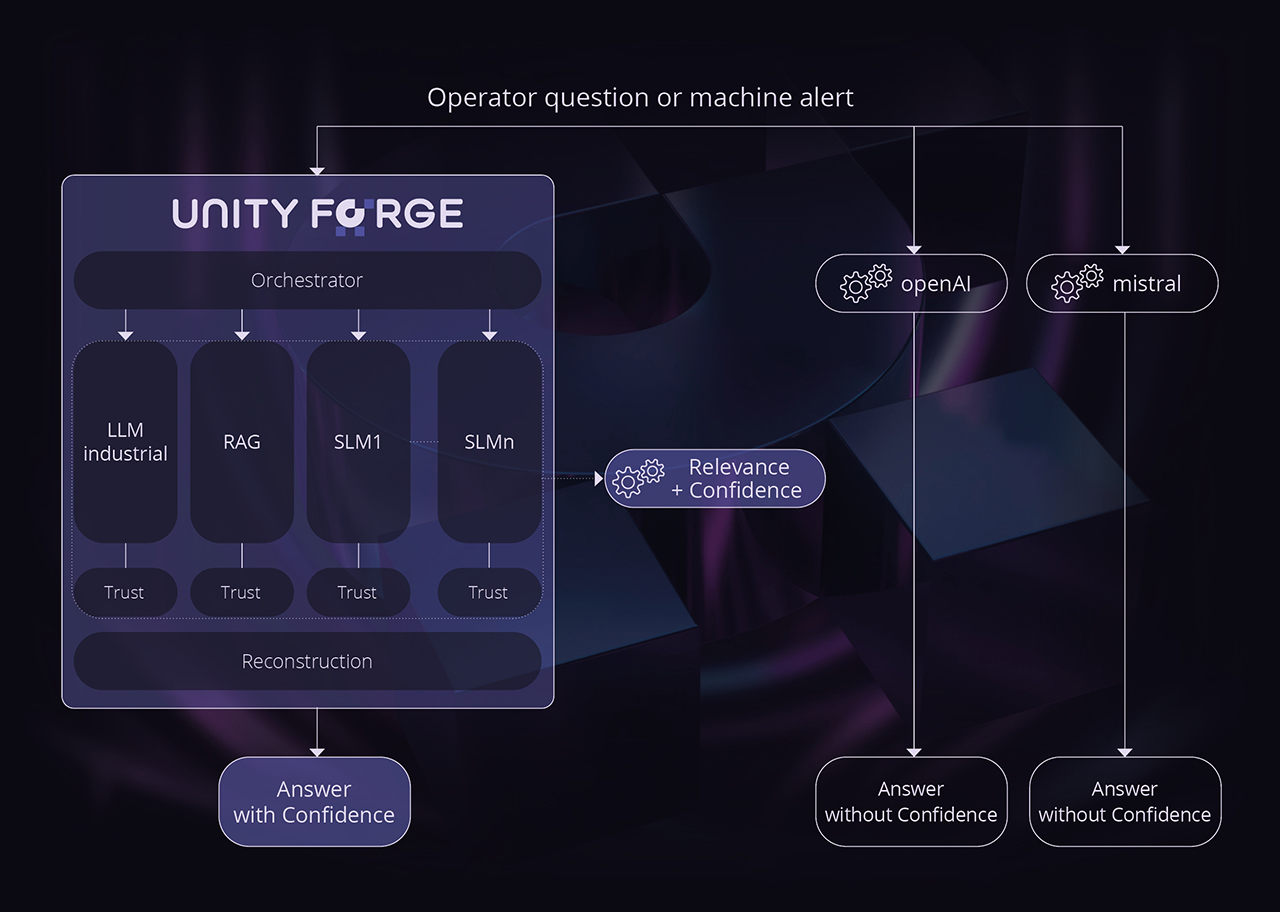

Why

reinvents industrial assistance

thanks to its unique architecture

The diagram below illustrates the architecture of Unity Forge

and highlights the fundamental differences

with the direct use of general-purpose language models

such as ChatGPT or other solutions on the market.

What makes

unique:

1

Specialized LLM

for industry

Unlike general-purpose models, Unity Forge is based on an LLM (Large Language Model) finetuned with industry-specific data. This enables it to understand the technical vocabulary, the industrial environment, and the precise needs of operators and machines.

2

Data base

enriched by each customer

Unity Forge doesn’t just respond. It feeds directly from technical documentation and proprietary data specific to each customer, guaranteeing answers perfectly adapted to the industrial context.

3

High-performance specialized models

Unity Forge also uses task-specific language models (SLMs). These models, though small in scope, excel in their field of expertise, ensuring precision and efficiency.

4

Confidence assessment for reliable answers

In industry, decisions are based on reliable data. Unity Forge systematically evaluates the uncertainty of generated answers. Only answers with a high level of confidence are selected and presented to the user.

5

Agentic

architecture driven

by an orchestrator

At the heart of the system, an intelligent orchestrator breaks down each request, whether it comes from a user or a machine. It identifies the bricks (LLM, SLM, RAG, etc.) most relevant to processing the request, then recomposes a tailor-made response adapted to the user’s expectations.

1

Specialized LLM for industry

Unlike general-purpose models, Unity Forge is based on an LLM (Large Language Model) finetuned with industry-specific data. This enables it to understand the technical vocabulary, the industrial environment, and the precise needs of operators and machines.

2

Data base enriched by each customer

Unity Forge doesn’t just respond. It feeds directly from technical documentation and proprietary data specific to each customer, guaranteeing answers perfectly adapted to the industrial context.

3

High-performance specialized models

Unity Forge also uses task-specific language models (SLMs). These models, though small in scope, excel in their field of expertise, ensuring precision and efficiency.

4

Confidence assessment for reliable answers

In industry, decisions are based on reliable data. Unity Forge systematically evaluates the uncertainty of generated answers. Only answers with a high level of confidence are selected and presented to the user.

5

Agentic architecture driven by an orchestrator

At the heart of the system, an intelligent orchestrator breaks down each request, whether it comes from a user or a machine. It identifies the bricks (LLM, SLM, RAG, etc.) most relevant to processing the request, then recomposes a tailor-made response adapted to the user’s expectations.

Why

outperforms general-purpose solutions

The direct use of generalist models, while useful for simple cases, cannot compete with the relevance, specialization and reliability offered by Unity Forge in complex industrial environments.

With Unity Forge, industrial companies have at their disposal a tool capable of transforming operations management by offering precise, tailored and reliable responses, where every interaction is optimized to boost productivity and reduce errors.

Watch

in action

Invest in the future

of industrial maintenance

Example of maintenance

Optimization

in a machine tool production plant

Context

A machine tool manufacturer regularly encounters breakdowns or maintenance needs on its complex equipment, made up of multiple mechanical, electrical and embedded software systems. Technicians often need to dig through extensive maintenance manuals, electrical schematics or instructional videos to diagnose problems and find solutions. This is time-consuming and increases the risk of human error.

How Unity Forge works

Integration of technical documents

Immediate access to relevant documentation

Fast, targeted search

Proactive recommendation

A strategic partner

for tomorrow’s industry

Cleia is a major player in the design and realization of customized, turnkey solutions for industry. With its engineering expertise and innovation-driven approach, Cleia supports its customers in transforming their production tools to make them more efficient, agile and resilient.

In close collaboration with Cleia, Omundu has developed integrated technological solutions, such as Unity Forge, which enhances the cleiaOS platform. This partnership is based on a shared vision: to revolutionize industry with intelligent, ergonomic and value-creating digital tools.

About us

20 years of industrial expertise

With 20 years’ experience in the manufacturing and aeronautics industries, Omundu is a key player in the integration of artificial intelligence for industrial maintenance. We understand the specific challenges faced by industrial companies, whether it’s reducing downtime, improving the efficiency of interventions or simplifying access to complex information.

Our team, driven by a culture of innovation and pragmatism, strives to offer tailor-made solutions that integrate seamlessly with existing processes.

With Omundu, artificial intelligence becomes an accessible lever for transforming your operations and meeting the industrial challenges of today and tomorrow.

Our mission

At Omundu, we strive to be the AI highest performer partner of industrial clients.

At Omundu, we firmly believe that artificial intelligence, in its current and accessible form, can bring tangible and immediate benefits to industry. Contrary to the fantasized image of AI conveyed by literature or the media, we harness the power of what we call “simple AI”: AI capable of reading, writing, understanding and processing information quickly and intelligently.

Immediate access

to essential technical documents.

Reduced search times.

Simplify complex diagnostics.

Our vision

We power a world where every document & machine talk – transforming industry, protecting the planet, and empowering people. We reinvent maintenance for the AI Era.

undertakes to:

Protect

your data

Our solutions are based on secure infrastructures, hosted in a private cloud or on your own servers, guaranteeing total control of your information.

Support

your teams

We offer ongoing support throughout the integration process, with a gradual build-up of your staff’s skills to ensure smooth, lasting adoption.

Innovate

with pragmatism

Every solution we develop is designed to meet concrete industrial needs, while maximizing the impact on your operations.

Encouraging continuous improvement

Our tools evolve thanks to user feedback and collected data, to keep pace with your requirements.

Our DNA

Our company name, Omundu, reflects deep values and a rich history. Inspired by the African philosophy Ubuntu, which means “Je suis parce que nous sommes”, Omundu embodies the importance of community, mutual support and shared humanity. This vision is reflected in our collaborative approach and our commitment to advancing the industry collectively.

The name Omundu also evokes “Le Monde” (The World), a nod to the international background of our founder, Vincent Lemonde, and his ambition to provide global and inclusive solutions. This dual heritage symbolizes our mission: to build bridges between technological innovation and human values, always keeping in mind a global perspective.

Our Logo:

Strong symbolism

The Omundu logo is inspired by the Adinkra symbol “Sankofa”, which means “to look back in order to go forward”. Traditionally represented by a bird looking back, this symbol expresses the importance of learning from the past to build a better future.

Reinterpreted by The Big Yellow Dog, in particular Pascal Colnel, this symbol has been adapted with an industrial touch to reflect our business sector. It perfectly embodies our approach: drawing on past experience to innovate and build a future where industrial performance and human values coexist harmoniously.

Our values:

Humanity at the heart of innovation

Omundu‘s values form the cornerstone

of our actions and strategic decisions

High Performance

We do one thing exceptionally well:

build the best AI-powered industrial

maintenance platform

to help our clients boost performance

and embrace the new AI era.

Innovation

We believe in technology that simplifies

and improves processes without unnecessary complexity.

We build open systems that benefit both

our clients and society.

Relocation

We enable industries to build locally.

Commitment & Diversity

Inspired by Ubuntu, we place people

at the heart of our mission.

Progress is a collective effort,

and we value the diversity of talent

needed to meet industrial challenges.

No Bullshit

We are the AI trusted partner.

If we know something, we say it.

Otherwise, we say we don’t know.

We want to be a trusted partner.

Sustainability & Privacy

We have a responsibility to build a sustainable future,

leaving no trace and no one behind.

Our users’ data belongs to them

– we respect and protect it.

Redistribution

We fund important causes such as cancer research,

brain disease research, environmental initiatives,

and poverty reduction.

Source

(Bio/Medicine)

We offer technology to make progress

in the medical fields.

At Omundu,

innovation is much more

than a tool,

it’s a means to building

a sustainable and inclusive future

for the industry.

Our values:

humanity

at the heart of innovation

Omundu‘s values form the cornerstone

of our actions and strategic decisions

High Performance

We do one thing exceptionally well:

build the best AI-powered industrial

maintenance platform

to help our clients boost performance

and embrace the new AI era.

Innovation

We believe in technology that simplifies

and improves processes

without unnecessary complexity.

We build open systems that benefit both

our clients and society.

Relocation

We enable industries to build locally.

Commitment

& Diversity

Inspired by Ubuntu, we place people

at the heart of our mission.

Progress is a collective effort,

and we value the diversity of talent

needed to meet industrial challenges.

No Bullshit

We are the AI trusted partner.

If we know something, we say it.

Otherwise, we say we don’t know.

We want to be a trusted partner.

Sustainability

& Privacy

We have a responsibility to build a sustainable future,

leaving no trace and no one behind.

Our users’ data belongs to them

– we respect and protect it.

Redistribution

We fund important causes such as cancer research,

brain disease research, environmental initiatives,

and poverty reduction.

Source

(Bio/Medicine)

We offer technology to make progress

in the medical fields.

At Omundu,

innovation is much more

than a tool,

it’s a means to building

a sustainable

and inclusive future

for the industry.

Our values:

Humanity

at the heart of innovation

Omundu‘s values form the cornerstone

of our actions and strategic decisions

High Performance

We do one thing exceptionally well:

build the best AI-powered industrial

maintenance platform

to help our clients boost performance

and embrace the new AI era.

Innovation

We believe in technology that simplifies

and improves processes

without unnecessary complexity.

We build open systems that benefit both

our clients and society.

Relocation

We enable industries to build locally.

Commitment

& Diversity

Inspired by Ubuntu, we place people

at the heart of our mission.

Progress is a collective effort,

and we value the diversity of talent

needed to meet industrial challenges.

No Bullshit

We are the AI trusted partner.

If we know something, we say it.

Otherwise, we say we don’t know.

We want to be a trusted partner.

Sustainability

& Privacy

We have a responsibility to build

a sustainable future,

leaving no trace and no one behind.

Our users’ data belongs to them

– we respect and protect it.

Redistribution

We fund important causes

such as cancer research,

brain disease research,

environmental initiatives,

and poverty reduction.

Source

(Bio/Medicine)

We offer technology to make progress

in the medical fields.